Bio based & biodegradable

fertiliser coatings

Microplastic pollution is a problem

Controlled Release Fertilisers (CRFs) currently rely on fossil fuel–based synthetic coatings, primarily polyolefins. In the EU alone, an estimated 8,000 tonnes of these polymers are applied to fertilisers each year, contributing to approximately 42,000 tonnes of microplastics entering the environment annually. These persistent plastics accumulate in soils, leach into waterways, and can enter the food chain, posing long-term risks to ecosystems and human health. In response to these growing concerns, forthcoming EU regulations are set to restrict or ban non-degradable fertiliser coatings from 2028.

Our Solution

We are developing bio-based and fully biodegradable coating systems for fertilisers such as NPK and Urea to replace the synthetic polymers that drive microplastic pollution and soil degradation. Using forestry-derived feedstocks (Cellulose), our coatings offer a truly circular, bio-based alternative that fully biodegrades in natural environments without leaving harmful residues. Our solutions are engineered to precisely control nutrient release rates, improving fertiliser efficiency while reducing environmental impact.

Why it matters

-

The technology is currently at TRL 3, representing an experimental proof of concept demonstrated through lab-scale formulation and field validation.

-

We use forestry-derived feedstock as a renewable, abundant and locally available source of cellulose, a bio-based polymer that provides the structural foundation for our biodegradable coatings.

-

Our coating technology is designed for CRFs with a target three-month nutrient release profile, ideal for golf courses, turf management, and high-value horticultural applications where precision nutrient delivery and environmental performance are essential.

FAQ’s

Prototype phase with Amber

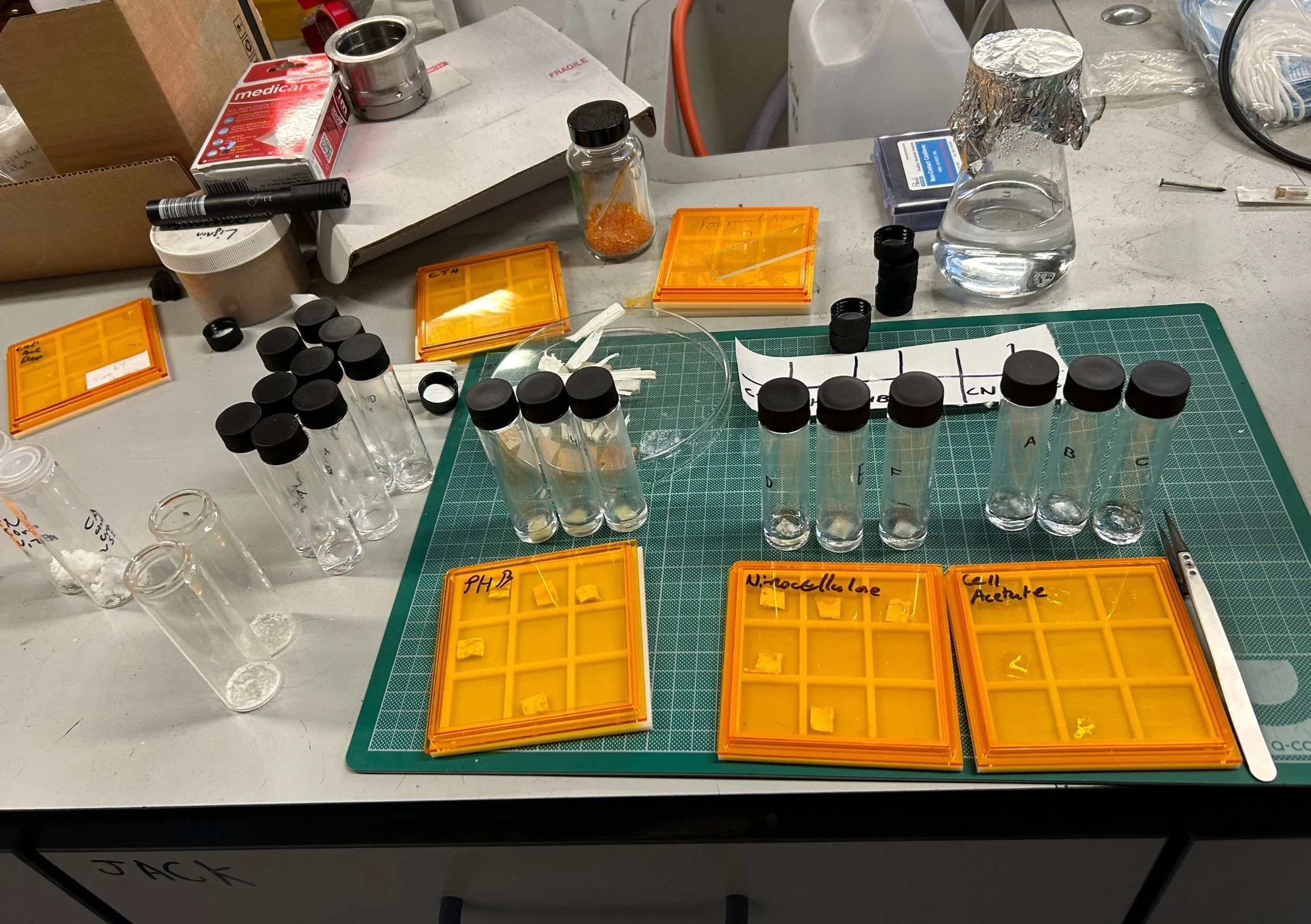

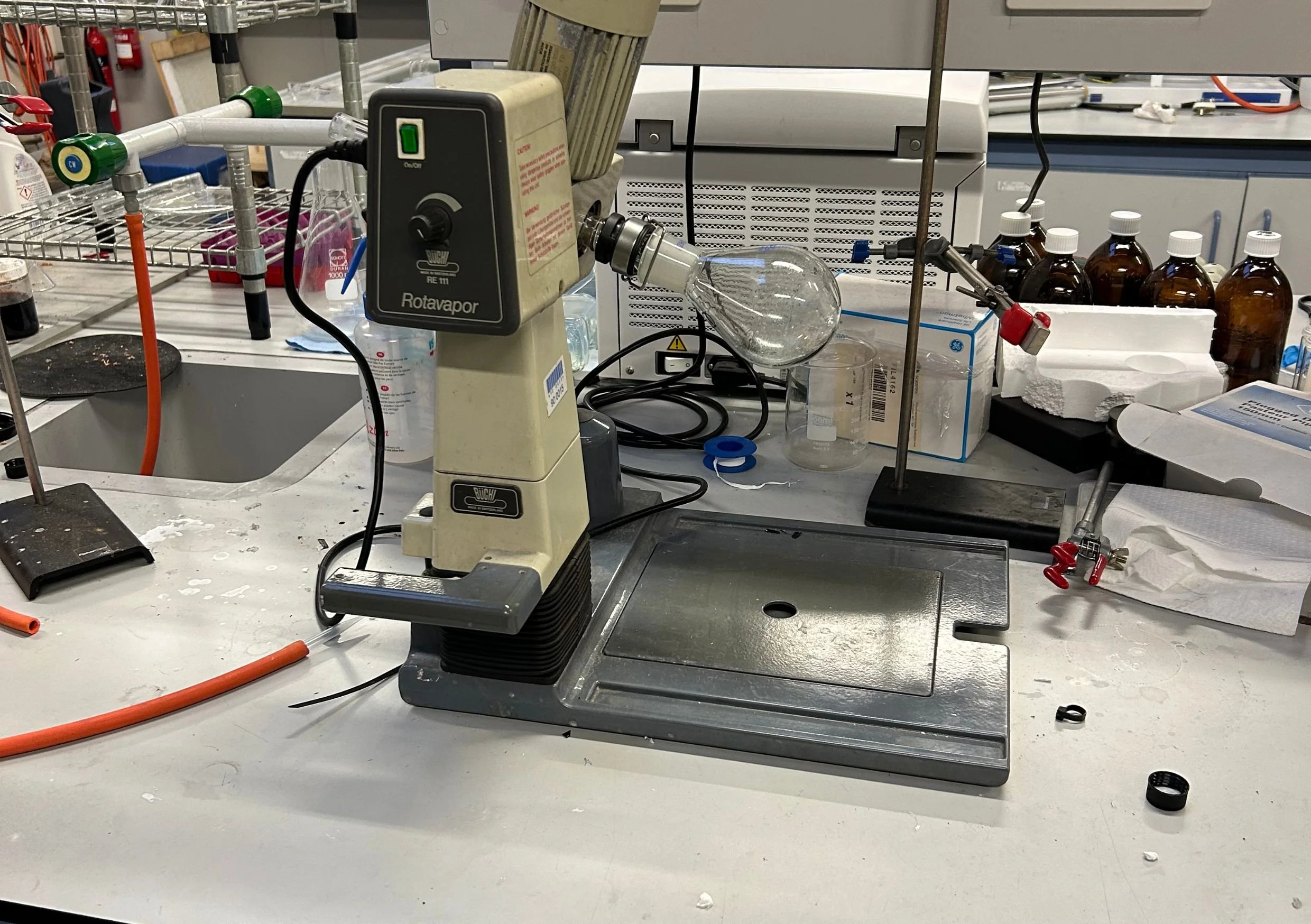

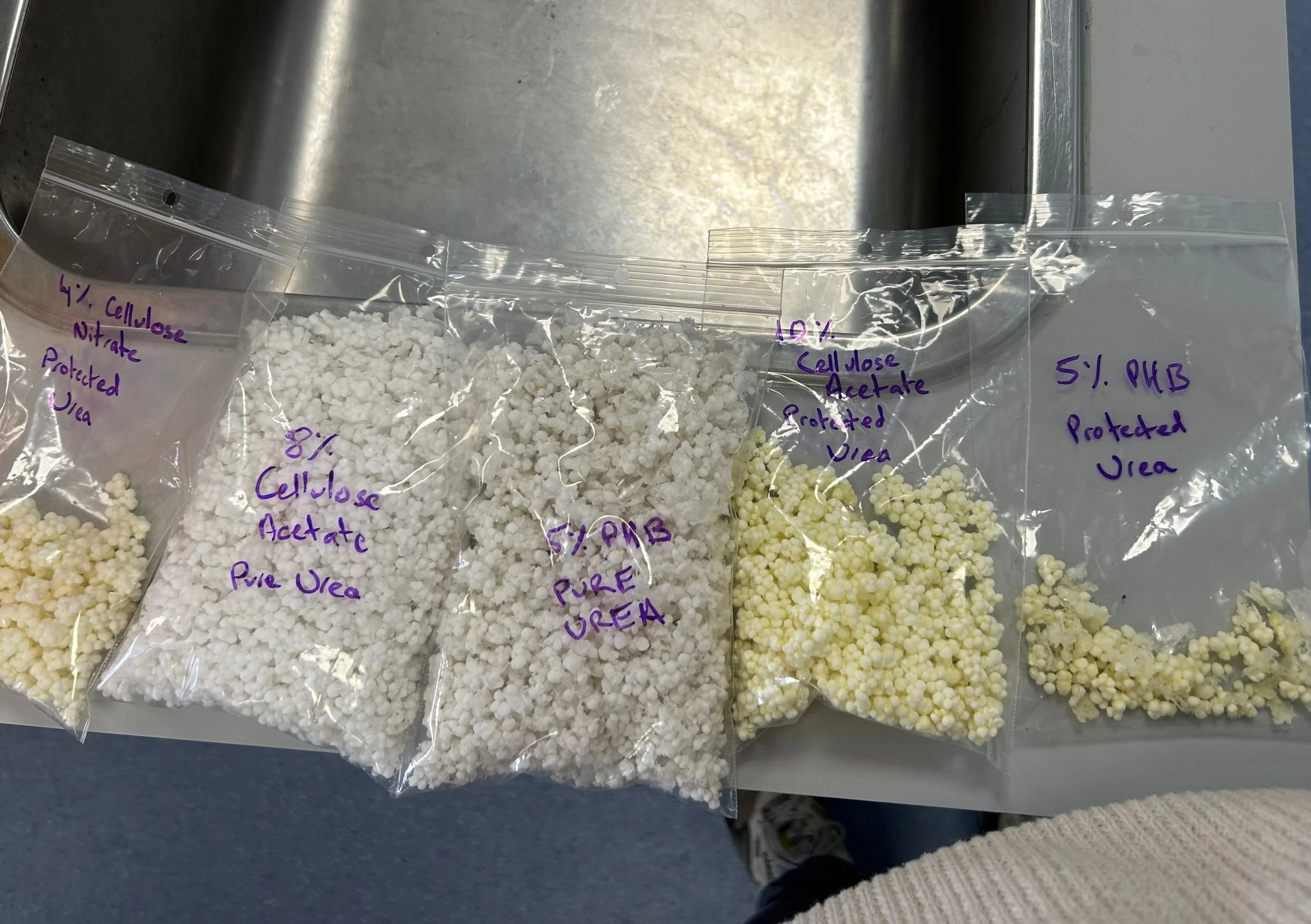

We developed our first generation of bio-based and biodegradable fertiliser coating prototypes. The work, conducted in the Trinity Chemistry labs, focused on the formulation, synthesis, and characterisation of six distinct biopolymer coating systems applied to untreated urea granules.

Each prototype was designed to evaluate key performance parameters, including coating adhesion, uniformity, nutrient release kinetics, and biodegradation behaviour under controlled laboratory conditions

Trials with UCD

Initial testing was conducted in UCD Growth Chambers, where key parameters such as nutrient release dynamics, plant growth response, and coating integrity were monitored under variable environmental regimes.

Following controlled-environment trials, the prototypes were further validated through field trials at UCD Lyons Farm, assessing real-world performance. The study successfully delivered TRL 3: experimental proof of concept, demonstrating the coatings’ potential to enhance nutrient efficiency while maintaining biodegradability and environmental safety.